On November 20, Ningbo Sunny Automotive Optech Co., Ltd. successfully held a review meeting in Shanghai for the group standard "Reliability Requirements and Testing Methods for Typical Optical Components in Automotive LiDAR". The meeting brought together ten experts from industry associations, research institutes, testing organizations, and LiDAR supply chain companies, along with the standard drafting team. They held in-depth discussions on reliability standards for core optical parts used in LiDAR systems.

At the meeting, the drafting team presented the background, development process, and main technical content of the standard. Experts carefully reviewed the draft, evaluating whether the parameters were practical, the coverage was complete, and the testing methods were easy to implement. They agreed that the standard is well-written, scientifically sound, and represents advanced domestic practice. The standard was approved and will be submitted to the China Association of Automobile Manufacturers for final approval. Its goal is to create clear reliability standards for LiDAR optical components, providing important guidance for product development and quality control.

From Setting Standards to Delivering Products: Sunny Leads with Optical Innovation

This new group standard doesn’t just set technical guidelines—it also gives clear direction on real-world performance and reliability for LiDAR products. Drawing on its deep understanding of high standards and technical know-how, Sunny Automotive Optech also took part in the "2025 International Forum on Automotive LiDAR Standards and Technology". At the event, Yang Jia, head of the R&D Center, gave a speech titled "Advancing LiDAR Mass Production Through Optical Innovation", sharing the optical breakthroughs and product results Sunny Automotive Optech has achieved by following high standards.

Mr. Yang Jia, Head of the R&D Center at Sunny Optical Automotive

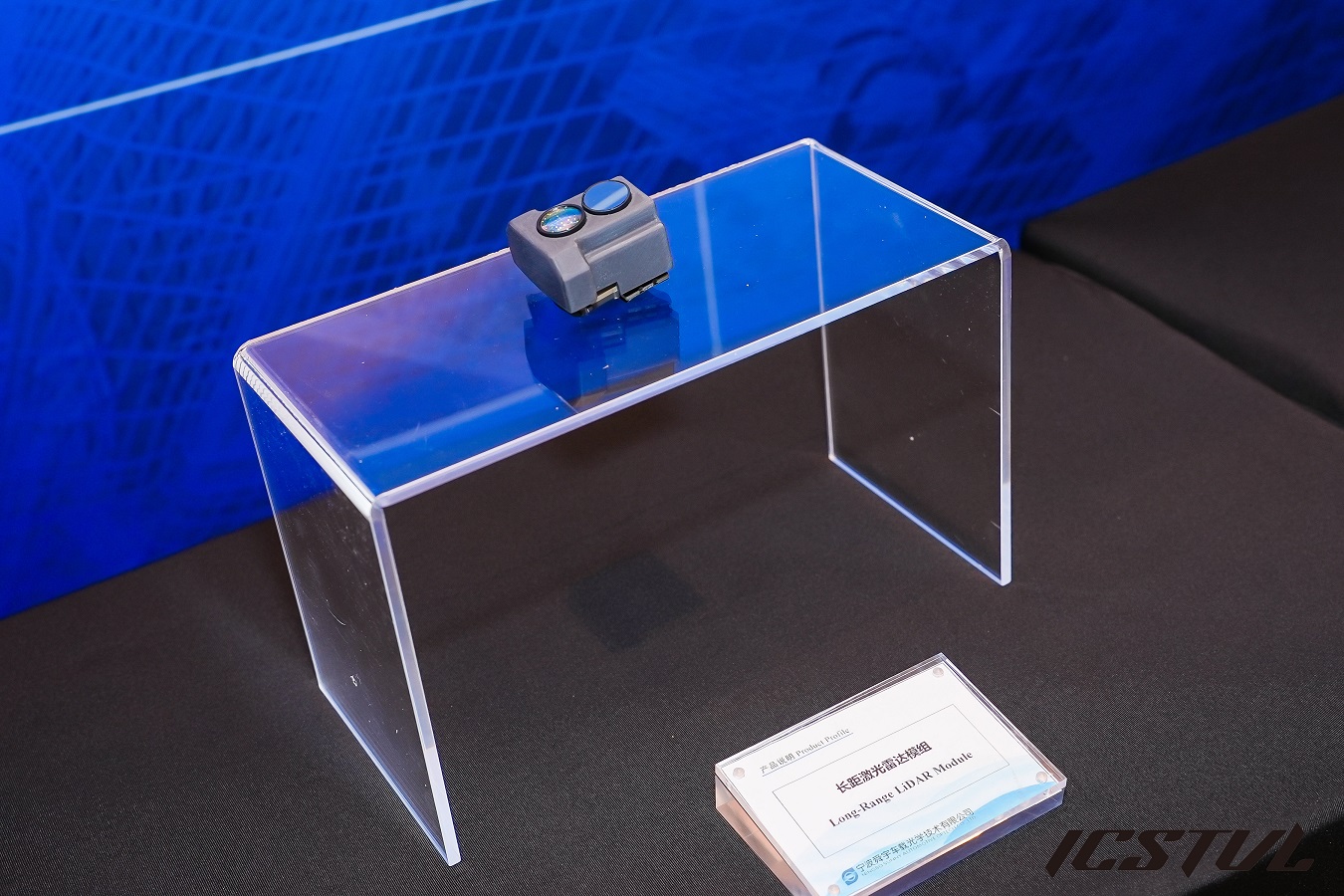

During the forum, Sunny Automotive Optech displayed two newly developed LiDAR module products, showing its strength in optical design, manufacturing, and mass production capability. These products are not only highly reliable and adaptable to different environments—they also prove Sunny Optical’s ability to turn standards into real, mass-produced products. The displays attracted the attention of many experts at the event, generating strong interest across the industry.

Combining Standards and Innovation to Drive High-Quality Industry Growth

From helping create industry standards to using those standards to spur innovation and mass production, Sunny Automotive Optech is building a cycle where better tech leads to better standards and products. The approval of this group standard helps align the industry on technical requirements for LiDAR optical parts, while also improving product quality and supporting healthy market growth. Looking ahead, Sunny Automotive Optech will continue to bring optical technology and standardization closer together, helping the LiDAR industry enter a more mature and efficient phase of development.

![[Exhibition Invitation] Sunny Automotive Optech Invites You to the 26th China International Optoelectronic Exposition (CIOE 2025) [Exhibition Invitation] Sunny Automotive Optech Invites You to the 26th China International Optoelectronic Exposition (CIOE 2025)](/uploads/image/20250908/首图7.webp)